Introduction

To reduce greenhouse gas (GHG) emissions from around the world to net (virtually) zero, there is a strong need to develop heating, ventilation, air conditioning, and refrigeration (HVACR) equipment that can minimalize the environmental impact. They will be equipment and systems that use refrigerants with low global warming potential (GWP) to realize a sound material-cycle society. In addition, smooth development and market introduction of high-efficient equipment using low GWP refrigerants, and establishment of refrigerant management systems for each county or region have been required. For the purpose, it is necessary to rapidly develop safety and reliability (and practicality) equipment and systems. It is also required that the amount of refrigerant charged is small, refrigerant leakage during operation is limited, and the refrigerant is completely recovered when the equipment / system is disposed of, even if the GWP of the refrigerant is low.

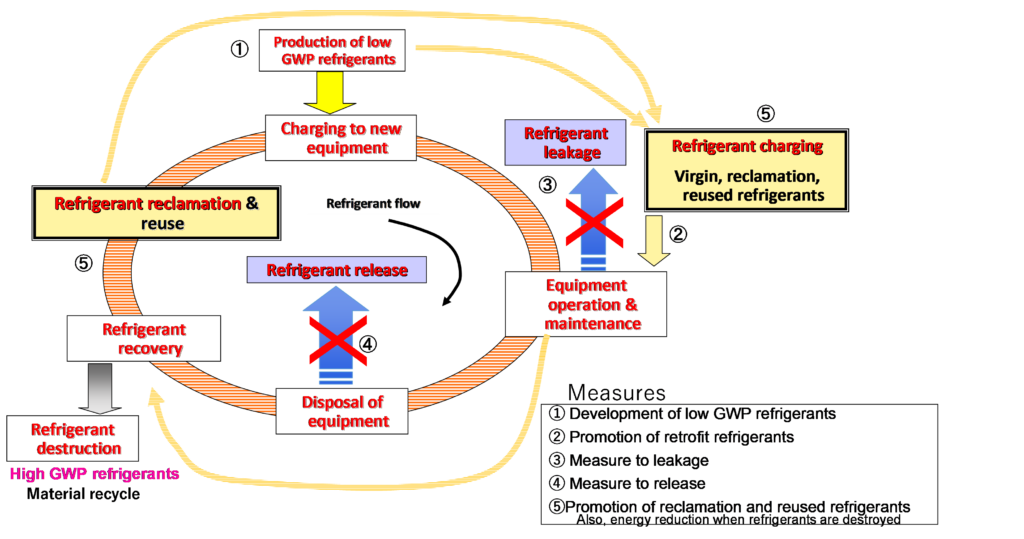

However, research and development and practical application of new refrigerants that can meet the same performance requirements as existing refrigerants have just begun. In this paper, the development status of low GWP refrigerants in Japan and the mass balance charts of refrigerant production, import / export, recovery, regeneration (reclamation / reuse), and destruction in the EU, US, Australia, and Japan will be introduced. Furthermore, equipment and mechanisms and refrigerant management circle (RMC, Fig.1) will be proposed with an example to realize a sound material-cycle society.

Developments of low GWP refrigerants in Japan(1)

Low GWP refrigerants including HFOs have been developed for some products such as household air conditioners (room air conditioner – RAC), air conditioners for stores and offices (packaged air conditioner – PAC), automobile air conditioners, condensing units, stationary type refrigerators and refrigerating units, and centralized refrigeration equipment. The typical GWP decreases between 1/1800 and one third. For example, the GWP of the refrigerants for RACs and small PACs have been reduced from 2090 (R 410A) to 675 (R 32), automobile air conditioners from 1430 (R 134a) to 1 or less (R 1234yf), centralized refrigeration equipment from 1810 (R 22) to 10 or less (R 717 NH3, R 744 CO2).

New refrigerants are under the development for some equipment products such as variable refrigerant flow (VRF) / variable refrigerant volume systems (VRV). Safety confirmation specified by safety code and available regulations have several issues, including flammability, toxicity, and stability as a practical refrigerant. This is because most of the new refrigerants developed have mild (safety code: A2L, B2L) / weak (A2, B2) / strong flammability (A3, B3). Also, some candidate refrigerants are nonazeotropic mixture whose temperature glides along the isobars in the two-phase region. They may have some problems in the operability, maintainability, and storability, including heat transfer characteristics of heat exchanger due to their complex thermophysical properties.

To maintain of the strict Kigali amendment schedule, the Government of Japan has decided to include some VRF / VRV as a designated product with a target value of 750 GWP. In addition, there is a possibility that RACs and air conditioners for automobiles with a gross vehicle mass of 7500 kg or more will be designated with a GWP of 150 or less. The above issues raise the bar for clearing more than ever but will be realized with new technologies and circumstances.

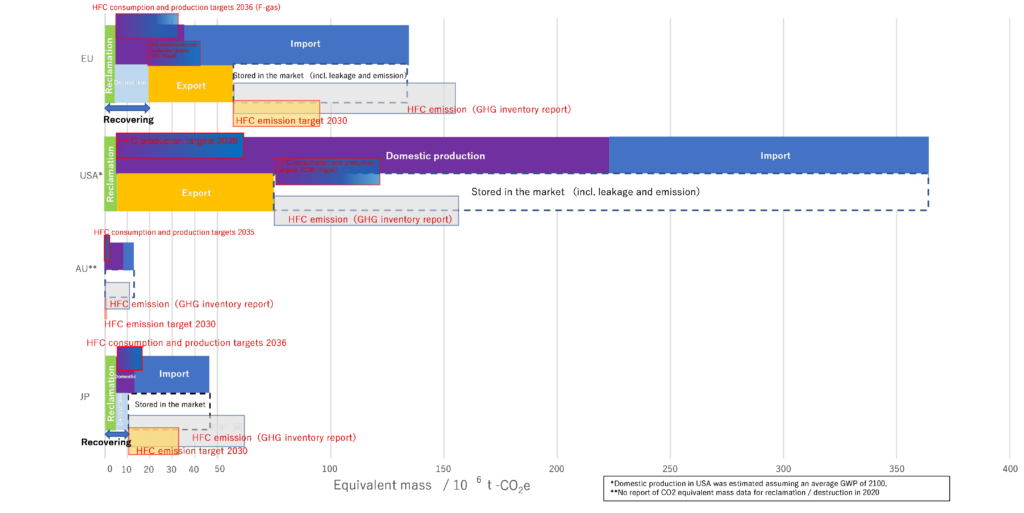

Upper row: domestic production / import / reclamation (supply side),

Lower: reclamation /destruction / export / stocked in market

Examples of low GWP equipment developments

RAC and PAC with R 32

There are small sprit air conditioners using R 32 for RACs and PACs. Approximately 10 million RACs sold in Japan use R 32 each year, and some PACs use R 32 under PAC safety standards. Less than or equal to 10 kW (cooling capacity) PAC satisfied the officially designated target of GWP 750 (product weighted average) in 2020.

Centralized refrigeration equipment with R 717 and R 744

Refrigeration systems have semi-hermetic interior permanent magnet, IPM, motors driving ammonia (R 717) screw compressors. Each compressor has a double economizer. The IPM motor driven by a variable frequency driver achieves 5 to 10 % higher efficiency than conventional induction motors. Other technologies that include shell and plate type heat exchanger for both condenser and evaporator, minimization of ammonia charge, and safety indirect cooling method (second refrigerant) with R 744. As the result, the power reduction ratio of installed cold storage warehouses can achieve up to 20 to 40 %.

Condensing unit and stationary type refrigerator with R 744

a. To improve the COP of CO2 (GWP=1) condensing unit, a cascade system was developed for convenience store, supermarket, cold room for food storage, and others. The unit can operate in middle temperature or / and low temperature application (different evaporating temperature operation). All-aluminium microchannel gas cooler is applied. A direct expansion system is applied in each loop in the case of one evaporator system.

b. A gas injection CO2 cycle to maintain the pressure between the connecting pipe and loading apparatus at an intermediate pressure was developed. New technologies are also applied, e.g., liquid injection from the gas injection pipe of the compressor to decrease the motor temperature, speed control of the gas cooler fan, and side by side gas cooler installation by a counter flow.

c. A two-stage compressor and refrigeration system with CO2 has been developed. The unique technologies are two-stage rotary compressor, mechanical subcooling refrigeration cycle, so-called split cycle, etc.

Hot water supply with R 744

Another pioneering development is household hot water heating units using CO2. Approximately 560 thousand units of CO2 household hot water heating units were sold in 2021, and 7.6 million units have been installed since 2001.

There are many developments with new low GWP refrigerants including natural refrigerants. Most of them require new technologies that increase the cost of COP (energy performance) improvement and maintenance under their legal or voluntary safety guidelines. There are many kinds of refrigerants including nonazeotropic mixtures / flammables, which have been developed for adequate use to satisfy all environmental requirements such as low carbon footprint and approach to SDGs. However, this will create new confusion in the HVACR field, which use a lot of different kinds of refrigerants.

Current situation in EU, USA, Australia, and Japan

As shown in the mass balance (mass equivalent to carbon dioxide emissions) of HFC refrigerants in 2020 (Fig. 2), the amount of refrigerant stored in the market being enclosed in equipment (partly leakage and emissions into the atmosphere) is gradually decreasing due to each measure. As the transition from CFC and HCFC refrigerants to HFC is progressing, HFC refrigerant emissions reported in the GHG inventory (grey bar in Fig. 2) are increasing.

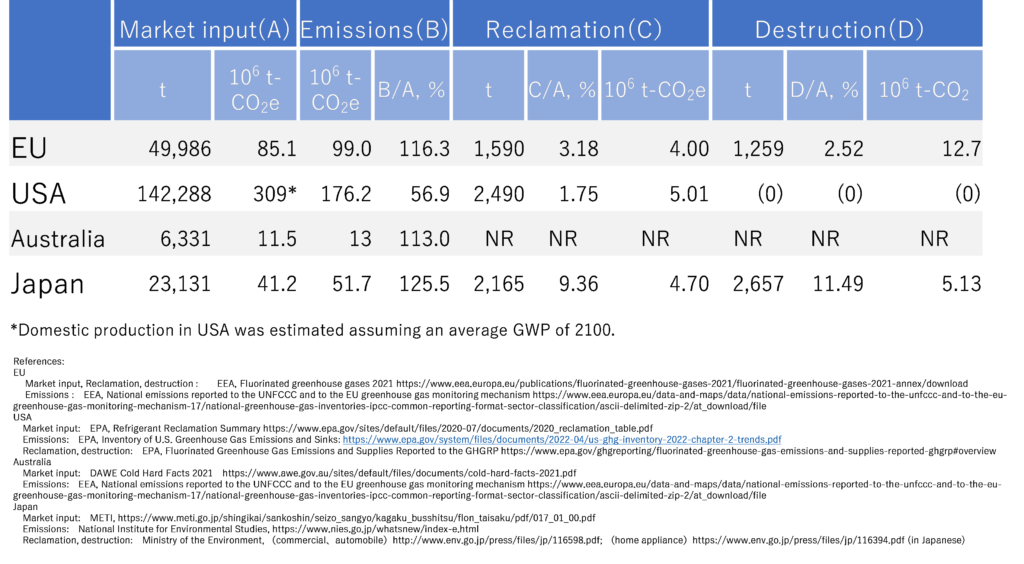

On the other hand, Japan’s Home Appliance Recycling Law and Automobile Recycling Law are clearly effective in improving the amount and recovery rate of fluorocarbons including CFC and HCFC. From this figure, the amount of reclaimed refrigerant distilled after recovery has increased, and that of destroyed refrigerant has decreased. The amount of reclaimed refrigerant is increasing year by year, which is almost the same as in the EU and US, but the ratio to Japanese market input amount is slightly higher (Table 1).

GHG emissions in Japan in 2020 will decrease by 38 million t-CO2e from 2019 to 1.15 billion t-CO2e due to improvements in the energy-saving technologies that have been energetically tackled since the oil crisis in the 1970s(2). Meanwhile, HFC refrigerant emissions (from all fields, but primarily from HAVCR, grey bar in Fig. 2) increased by 2.0 million t-CO2e from 2019 to 51.7 million t-CO2e (2). As shown in Fig. 2, the actual consumption value of HFC refrigerants (= domestic production + import) in 2020 was about 41.2 million t-CO2e, a decrease of about 8 million t-CO2e from 2019.

In order to further improve the effectiveness of measures against the refrigerant problems, HFC refrigerants were added to the regulatory target in 2018 under the “Ozone Layer Protection Law” that regulates CFC and HCFC refrigerants. With the Kigali Amendment, several measures such as the production and consumption regulation of HFC refrigerants have been taken (the blue-purple bar graph in Fig. 2 is the target value for 2036). Since Japan’s Freon Emission Control Law was revised in 2020 and penalties were strengthened, so it is expected that the refrigerant recovery rate will improve significantly.

Refrigerant management circle, RMC

Even with the successful developments of some new low GWP refrigerants and their equipment unit, the RMC remains important (Fig. 1). Because low GWP refrigerants are fluorinated compounds, they are valuable resources and need to be recovered. Also, conventional refrigerants being still in use, must be recovered. The same applies to natural refrigerants but they are more careful and safer. To realize the refrigerant management circle, some task systems must be built as follows.

(1) Leakage reduction during equipment operation: It is necessary to investigate the cause. There is a high possibility of leakage from connectors and additional parts during installation, and there is leakage due to long-term operation or aging of compressors, heat exchangers, piping, etc.

(2) Emissions Reduction when disposing of equipment: It is effective in improving the recovery rate by reducing the emissions. Both the development of refrigerant recovery device and the design of HVACR equipment that can easily recover refrigerant are desired. For flammable refrigerants, proper and safe treatment, including recovery is required.

(3) Regeneration of recovered refrigerant: Reclamation (distillation, component adjustment for mixtures) and recycling (simple regeneration) of the recovered low GWP refrigerants should lead to reduction of the refrigerant production amount, reduction of the refrigerant leakage, and improvement of the recovery rate. Refrigerant destruction and production energy is about 20 times that of refrigerant reclamation (low carbon footprint). Furthermore, the regeneration makes effective use of earth resources (low ecological footprint).

(4) Destruction of unwanted refrigerants: Destruction, especially high GWP refrigerants, is effective. To realize a sound material-cycle society, it is desirable to destroy the refrigerants and use decomposed materials to produce low GWP refrigerants or other products.

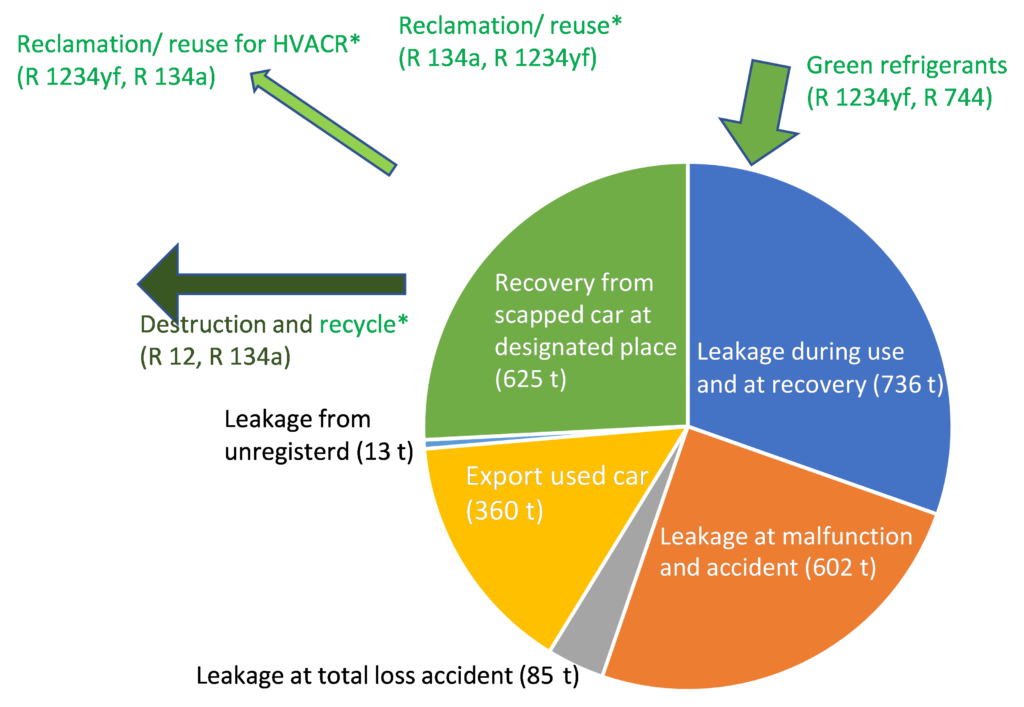

As an example of RMC, Fig. 3 shows the mass balance of HFC automobile air-conditioner refrigerants (R 134a) in Japan. By using of the low GWP refrigerants (R 1234fy, R 744), the leakage during use can be reduced. For maintenance, e.g., accidents, and malfunctions, priority is given to the reclaimed / recycled refrigerant (R 134a, R 1234yf) recovered from scrapped vehicles. Some of them can be used as composition of new low GWP refrigerant mixtures with HFO / natural refrigerants. Also the higher GWP refrigerants (R 12, R 134a) among the recovered ones must be systematically destroyed and would be chemically recycled.

Conclusions and proposals

For reducing the HFC emissions with the larger environmental impact among GHGs, as introduced in this paper, improving the recovery rate of the conventional fluorocarbon refrigerants is an important issue. One measure to improve the recovery rate should be to apply economic methods. Currently, in Japan, there is nothing unique other than recycle tickets of automobile air conditioners and home appliances, and penalties for each law and regulation related to the Kigali amendment (HFC consumption and production restrictions) and the Paris agreement (HFC leakage reduction and emission ban). Of course, they are working well, but they won’t be enough in the future.

At that time, it is desirable to take measures to popularize reclaimed refrigerants and to establish comprehensive energy management and refrigerant circular economy (reduce / reuse / recycle) by RMC not only for conventional refrigerants but for new ones. It is friendly to both the environmental earth (material-cycle society) and users of the HVACR systems. Therefore, both RMC and low GWP refrigerant are elements to a carbon-neutral society by 2050.

Noboru Kagawa

References

- Kagawa, N., Recent Refrigerant and System Developments in Japan, Industria & formazione –international special issue 2019-20, 34-37, Centro Studi Galileo

- National Institute for Environmental Studies, https://www.nies.go.jp/whatsnew/index-e.html