While a great deal of progress has been made on the transition from HFC refrigerants to the next-generation, low-GWP alternatives, a considerable amount of work remains before we can declare global victory and begin to focus our attention elsewhere. This paper will explore the current state of the HFC phase down In the United States, including the latest EPA initiatives, building code efforts in the states, lessons we’ve learned from others’ F-gas experiences, and efforts to educate technicians on safe handling of alternative refrigerants and strategies to curb releases of refrigerants into the atmosphere.

As I write this, the United States Senate is poised to consider the ratification of the Kigali Amendment to the Montreal Protocol, the global HFC phase down treaty already ratified by nearly 130 countries. While we are confident of ratification, it’s important to remember that such an action requires the assent of two-thirds of those Senators present and voting (67 votes if all 100 Senators are present). The United States Constitution deliberately makes treaty ratification challenging, and today, in an election year, with a Senate nearly equally divided between Democrats and Republicans, it is particularly difficult, and time is of the essence. Even so, Kigali ratification is strongly supported by industry and the environmental community alike, so we remain committed and confident.

How We Got Here

So, how did we get here – standing on the brink of success? The journey was long and arduous, as any monumental, worthy path is likely to be. Planning, research, collaboration, and continuous communication were all key to the effort’s ultimate success.

It began with a well-thought-out plan, one that the HVACR industry has followed assiduously and doggedly for well over 10 years, bringing together disparate communities united in this case by a common goal: The essential, global replacement of a class of refrigerants that, while hugely successful in terms of efficiency, affordability, and availability, have proven to be too environmentally detrimental to continue in widespread use.

Even as the industry began meeting with Obama Administration officials and friends in the environmental community in the early 2010s, AHRI’s research arm – the Air-Conditioning, Heating, and Refrigeration Technology Institute – embarked on a major research project to identify the generation of refrigerants to take the place of HFCs. If the industry was going to transition from HFCs, it had to be certain the replacements would be suitable – efficient, affordable, and plentiful. We will discuss this further, below.

Even though industry and the environmental community agreed with respect to phasing down HFCs, convincing administration officials in the White House, the Department of Energy, the Environmental Protection Agency, and the Department of State that the United States needed to lead the charge on such an ambitious undertaking took considerable time and effort. While we are sure this is not the case in Europe, aligning the needs, wants, and priorities of three federal agencies and their superiors in the White House can be akin to trying to line up rows of empty bottles on the deck of a ship during a storm.

But as nations, regions, and U.S. states accelerated their individual phase down plans, the disparate entities came together and what became known as the Kigali Amendment was formed and perfected, ultimately being approved by the Meeting of the Parties in October of 2016.

Implementing Legislation

That inspiring and exciting day marked only the beginning of the process, however, for even though many other nations quickly ratified the agreement, the United States’ political situation was upended by the unexpected election of Donald Trump, who had campaigned on withdrawing his country from the Paris Agreement, putting the fate of Kigali in doubt.

Even though President Trump never publicly uttered a word one way or the other about the Kigali Amendment, he also never sent it to the Senate. What he did do, in the waning days of his administration, is sign legislation containing a national phase down structure mirroring that in the Kigali Amendment — a very key accomplishment for our industry, particularly during a very heated election year. That legislation – the American Innovation and Manufacturing (AIM) Act – gave the Environmental Protection Agency the authority to regulate high-GWP refrigerants.

Research

As mentioned earlier, committed at the beginning of this process to the research necessary to identify the next generation of refrigerants to take the place of HFCs. From testing to modeling to servicing to detection, the industry has spent more than US$7 million on more than 11 research projects to ensure continuity of the health, safety, comfort and productivity provided by the products and equipment we make.

Work That Remains

In addition to Kigali Amendment ratification – which is important to protect U.S. manufacturers in the global marketplace – significant challenges remain for our industry in the areas of building and fire code development and updates and education and training, both in the U.S. and around the world.

That’s because the most promising refrigerants identified are classified by ASHRAE as A2L (low flammability). Our extensive research program provided the scientific basis to update safety standards for the use of new refrigerants. The new safety standards must be adopted into building codes across the United States So, after the challenge of securing U.S. commitment and leadership for the Kigali Amendment and the challenge of identifying suitable alternatives, the challenge for our industry now is to successfully update safety and building codes to enable the use of the alternative refrigerants identified by our decade-long research program. A significant part of that challenge has been to convince the fire service of the relative safety of these new refrigerants – a process that has been underway for several years and has resulted in the first refrigerant training developed by firefighters for firefighters based on a demonstration project showing first responders how refrigerants behave in a fire.

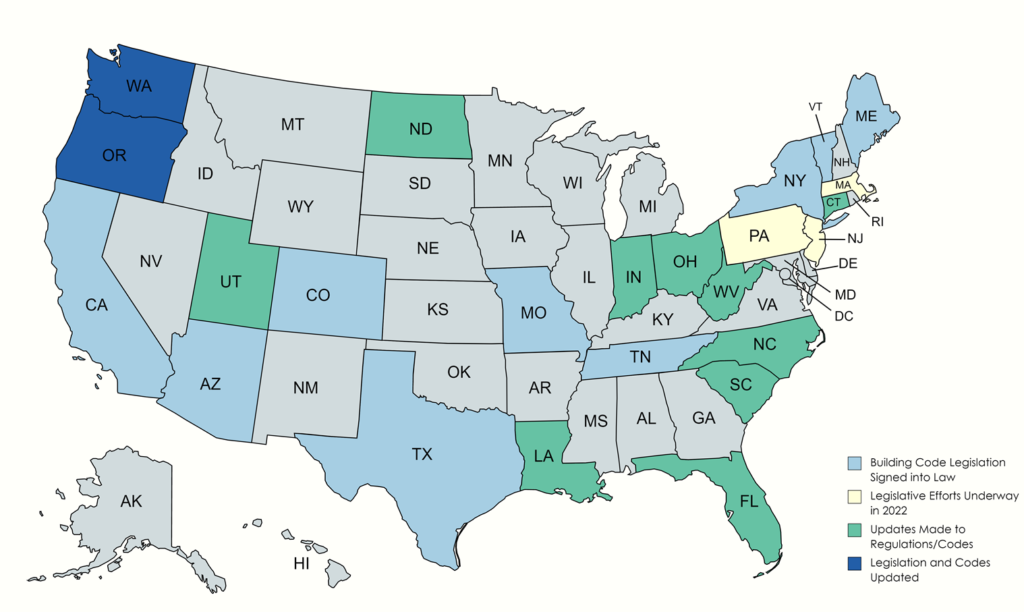

And the success of that effort has led to numerous states now accepting the use of A2L refrigerants (shown here in dark green and light blue), in a process that is ongoing. AHRI and its members have been unrelenting in our efforts to revise current building codes to allow A2L use and also to convince cities and state legislatures to allow their use. As you can see from the map, this effort is far from over, but considering that we began with grey states from sea-to-sea, we have met with considerable success thus far.

As part of the standards updating process, ANSI/ASHRAE Standard 15.2 was recently approved and is expected to publish shortly as the USA’s first application standard specific to residential air conditioning. This standard includes inputs from seven public reviews as well as findings from the latest industry research.

With the move to lower-global warming potential refrigerants, more rigorous application safety requirements were required for residential systems, which led to the creation of this new standard. ASHRAE 15.2 was crafted with the building codes in mind and is designed so that it can be readily understood and applied by a wide range of stakeholders. Efforts were also made, where possible, to harmonize requirements with the existing ANSI/ASHRAE 15 standard, as well as the UL 60335-2-40.

Once codes allow widespread A2L use, proper technician training is essential to enable a seamless transition for consumers. AHRI has been working with its colleagues in the contractor and distributor community as well as with North American Technician Excellence – the technician certification authority – to ensure those who install and maintain equipment are trained in proper A2L handling techniques and protocols. In addition, all the research findings have been made available to the firefighting community and code officials. These are very significant steps and victories on our refrigerant transition path, and it has taken the combined efforts of manufacturers, government agencies, laboratories, and others to accomplish them.

Transportation and Allocations

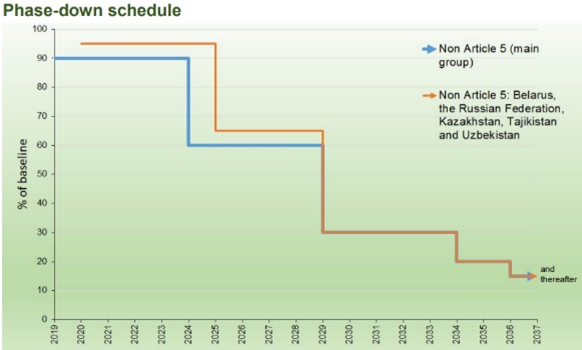

The AIM Act mandated that the EPA implement a national HFC phase down, a process that will be accomplished through the use of allocations, i.e., gradually tightening HFC supplies, as was the case in the transition from HCFCs to HFCs. The next significant step-down is in 2024, when the U.S. and other developed (A2) nations will need to reduce HFC use 40 percent compared to the baseline – not a small feat. That looming deadline makes it imperative that building codes and state laws be changed to allow the use of A2Ls. The EPA already has done its part on the national level, allowing the use of A2Ls in residential and light commercial air conditioning beginning in May 2021, subject to safety standards. Such refrigerants already were permitted for use in auto air conditioners (2011) and window units and PTACs (2015).

Summary

This process is tantalizingly close to completion with respect to the technical implementation details, and we are confident that at this point next year, we will be able to state that there’s little left but the rest of the phase down steps and ongoing technician training. It has been an admirable collective effort and one for which the industry can be very proud.

Helen Walter-Terrinoni