The Mobile Air Conditioning system (MAC) with its direct and indirect emissions has still a relevant environmental impact, this, despite the relevant and effective efforts made in the last decades for reducing it.

Last developments and agreements on GHG (Green House Gases) and other environmental issues are asking for achieving the total decarbonization of road transport by 2050 in most of the World Regions. The mainstream technology selected for achieving these targets is the electrification of vehicles (electric vehicles). The Mobile Air Conditioning is part of this scenario and will evolve in this direction by becoming part of a more complex vehicle thermal management system.

In this context, recent studies have identified some risks associated with substances (e.g., PFAS) used as component in in the used refrigerant. Within the MAC scenario as well, the elimination of such substances and the replacement of current refrigerant with sustainable substances has become necessary.

This paper focuses on the European Region and illustrates some details on the electrification scenario and on the alternative technologies under development to face the incoming transition.

CLIMATE CHANGE AND LIGHT DUTY VEHICLE ELECTRIFICATION

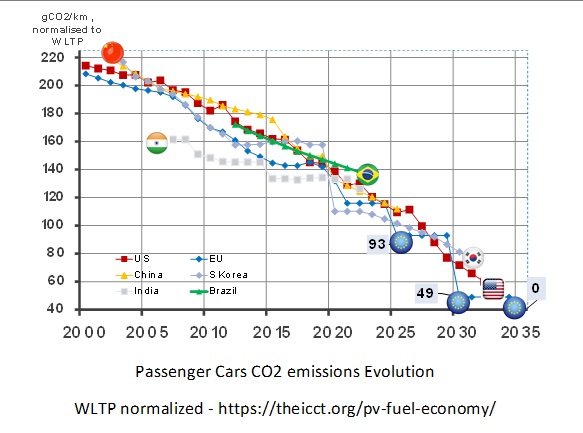

To contrast the Climate Change, there is a worldwide common objective to achieve the road transport decarbonization by 2050 (UNCOP21). To achieve this goal, several world regions set or planned to establish regulations aiming to reach zero CO2 emission at tailpipe of light and heavy-duty vehicles by 2035-2040.

The mainstream technology to achieve this ambitious target is Battery Electric Vehicle (BEV) together with the availability of decarbonized electricity (renewables or nuclear).

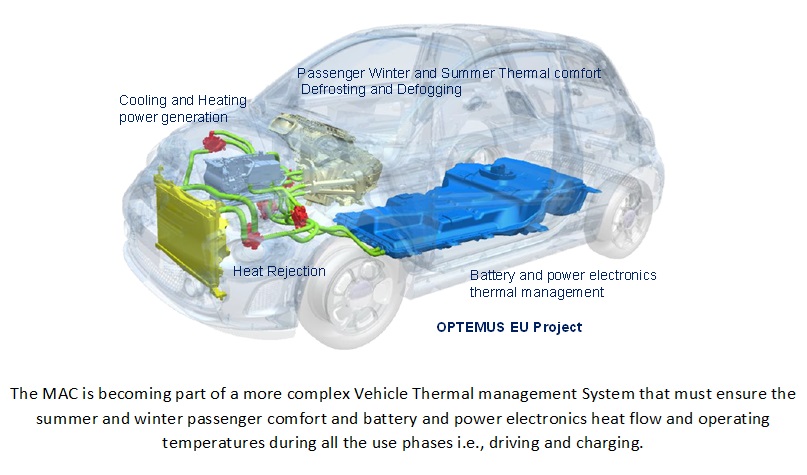

A BEV is a vehicle powered by an electric motor that draws electricity from a battery and is capable of being charged from an external source. To ensure the maximum efficiency and reliability of the battery and the power electronics need a thermal management system with the function to limit the operating temperature in a defined range. In addition, the available waste heat is not enough and at low temperature (e.g., 40°C) to ensure the passenger winter comfort and the safety functions (de-icing and defogging).

For these reasons the Mobile Air Conditioning (MAC) is becoming a more complex system which needs to be able to ensure the passenger summer and winter comfort and that the battery and power electronics are under optimal operating conditions in all weather conditions. In order to ensure all these functions, a modular system seems one of the preferred options, i.e., electric compressor, chiller, water cooler condenser form a module, where the refrigerant is hermetically sealed and only coolant lines come out. The module can be placed where it is more convenient. In a BEV the compressor is electric, so it can be part of a hermetic system where the heating and cooling power are managed by means of a secondary coolant. The main characteristics of this approach are:

- the refrigerant can be even flammable, there will be no risk to have leak in the passenger compartment;

- the quantity of refrigerant can be minimized;

- the heat pump function is ensured avoiding to reverse the thermodynamic cycle.

MOBILE AIR CONDITIONING: ENERGY EFFICIENCY AND CARBON FOOTPRINT

The energy demand of a MAC on electric vehicles is relevant both in summer and in winter. Recent studies [JRC2024] show that the MAC in real world use in the European region can increase the BEV energy consumption up to 40% in winter and up to 35% in summer, while on average the effect on vehicle efficiency and increase of energy consumption is about 20%.

Considering for a generic BEV a consumption of 15 kWh/100km, the average impact of the MAC and related thermal system is about 3 kWh/100km. Assuming that the electricity carbon footprint is about 200g CO2/kWh [2024eea] and a vehicle with a lifespan of 250’000 km, the use of MAC generates 1.5t CO2e only in all its operating life.

Considering that the MAC system weight should not exceed 30 kg and that on average the carbon footprint of components, their production and recycle is of about 4kg CO2/kg, the carbon footprint of a BEV MAC and related thermal system is about 108kg, far less than the use phase.

So, the improvement of the MAC efficiency is crucial to lower the impact on BEV electric range and, to lower the overall vehicle energy demand and, consecutively, the carbon footprint.

FUTURE MAC TECHNOLOGIES AND PFAS ISSUE

The HFO-1234yf with ozone depletion potential (ODP) value of 0 and Global Warming Potential (GWP) value of 4 is the refrigerant in use in Europe in vapor compression cycles for mobile air conditioning.

Recently a movement led by five European countries (D, DK, NL, NO, SE) asked actions to limit or remove any substance containing or generating PFAS (Perfluoroalkyl and Polyfluoroalkyl Substances) [ECHA, 2023], the HFO-1234yf is one of those substances.

Therefore, the OEMS and suppliers launched projects and initiatives to reconsider their position with respect to the use of natural refrigerants (R-774, HC-290) or with respect to non-PFAS substances such as the HFC-152a or mixtures.

The still quite high cost of the HFC-1234yf makes the natural refrigerants and in particular the HC-290 a quite attractive option also in perspective of the transition to low GWP refrigerants and to light duty vehicles electrification where the HFO-1236yf is the mainstream [2024MARTHUR] and also, where the HFC-134a is still widely used [2024LI].

CONCLUSIONS

The Mobile Air conditioning system is facing a new relevant evolutionary phase driven by the need to further reduce its direct and indirect environmental impact.

On one hand, the progressive electrification requires to review the MAC design by making it a more complex system to ensure the passenger thermal comfort and the optimal battery operating conditions. The system complexity increase is leading the engineers to using dual-loop systems that allow a reduction of the system size, an easier management of the BEV complex lay-out and to reduce the refrigerant quantity.

On the other, the risk of a ban or use limitation of HFO-1234yf due to the PFAS issue is leading the industry to reconsider the current refrigerant and act proactively to protect the environment.

References

UNCOP21, https://unfccc.int/process-and-meetings/the-paris-agreement

2024JRC, A practical exploration of Battery Electric Vehicles range and environmental impact based on real-world data, A. Tansini et al., 24CO-0068CO2Reduction for Transportation Systems Conference, Turin 2024

2024eea, https://www.eea.europa.eu/en/analysis/indicators/greenhouse-gas-emission-intensity-of-1

2024ECHA https://echa.europa.eu/it/hot-topics/perfluoroalkyl-chemicals-pfas

2024LI, The emission reduction potential and cost effectiveness of low-GWP refrigerants in electric vehicle air conditionings. Li A, Yu B, Zhang Y, Ouyang H, Guo Z, Shi J, Chen J. Carbon Footprints 2024;3:6. https://dx.doi.org/10. 20517/cf.2023.54

2024MATHUR, Mathur, G., “Using Natural Refrigerants Propane (R290) & Carbon Dioxide (R744) as Direct & or Indirect Heat Pump Systems to Address PFAS Issue,” SAE Technical Paper 2024-01-2876, 2024, doi:10.4271/2024-01-2876.

Carloandrea Malvicino