Enerblue is founded in 2007 in the highly specialized, technologically advanced eastern Veneto area. Driven by young and dynamic people, the desire is to make the most of the outstanding heating and air conditioning know-how within this industrial district.

Global warming and the progressive need to reduce CO2 emissions demand led Enerblue to make green and future-oriented choices. Sustainability led us to develop heat pumps that use natural refrigerants since 2012.

In a few years the development of product catalogue is important: after the first prototype of Co2 heat pumps, in 2014 chillers first and then heat pumps charged with R290 become part of the journey.

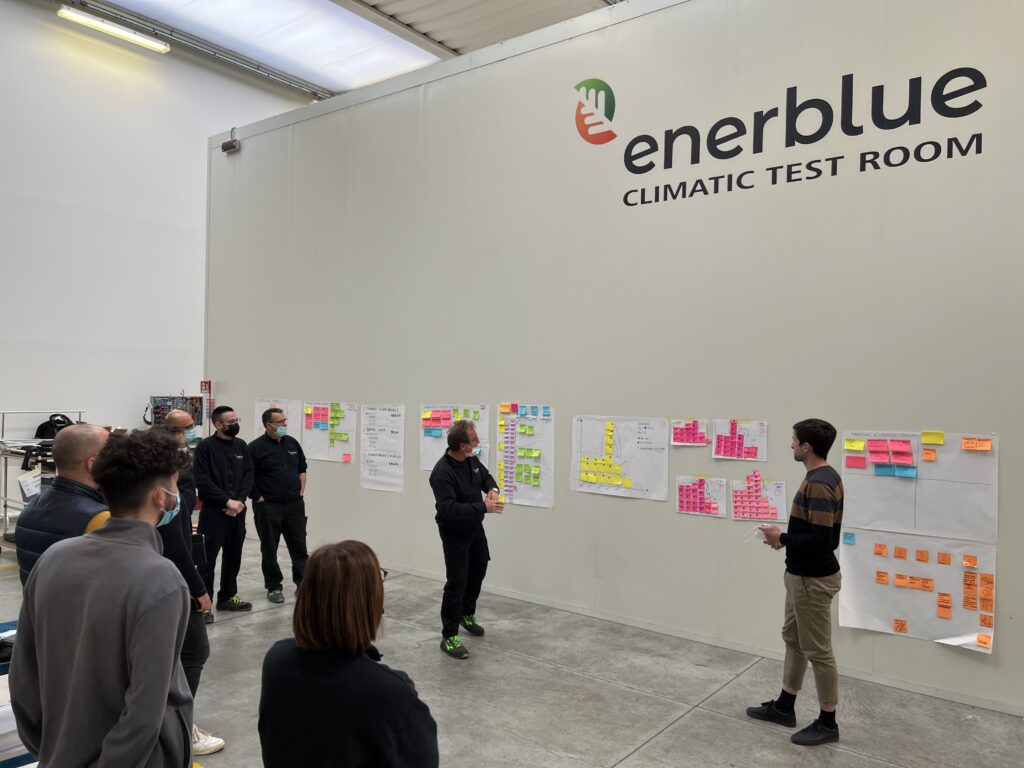

Climatic chamber

ENERBLUE Lab was established out of the need to support company innovation programs (i.e. research into new technology and continuous improvement) and so obtain more reliable, environmentally sustainable units.

The test lab allows us to check performances and ensure product quality certification.

The various stages of testing are carried out on all products:

- Heat pumps and chillers up to a power rating of 350 kW – simulated ambient temperature from -15 °C to 45 °C and relative humidity from 20 to 100%.

- Total-recovery heat pumps (DWS), in air-to-water and water-to-water versions.

- Chillers with integrated free-cooling module

Tests are conducted in accordance with the regulations EN 14511 and EN 14825. Moreover climatic chamber is built for testing refrigerant gas A2L and A3.

CO2 Heat Pumps

Units for the production of very high temperature water with natural refrigerant gas (CO2). Our range uses R744 (CO2) refrigerant gas and can reach hot water temperatures up to 90°C with an external air temperature of -20°C.

Thanks to the experience and deep studies , our technicians have been able to facilitate an innovative heating system to distributors using a simple calculation interface. With a few simple data such as daily consumption profile required by the project, required / available water temperature and some more, designers are increasingly passionate about the CO2 system, finding a field of application that can easily replace the traditional heating provided by oil fired boilers. Not only green and sustainable but also cheaper.

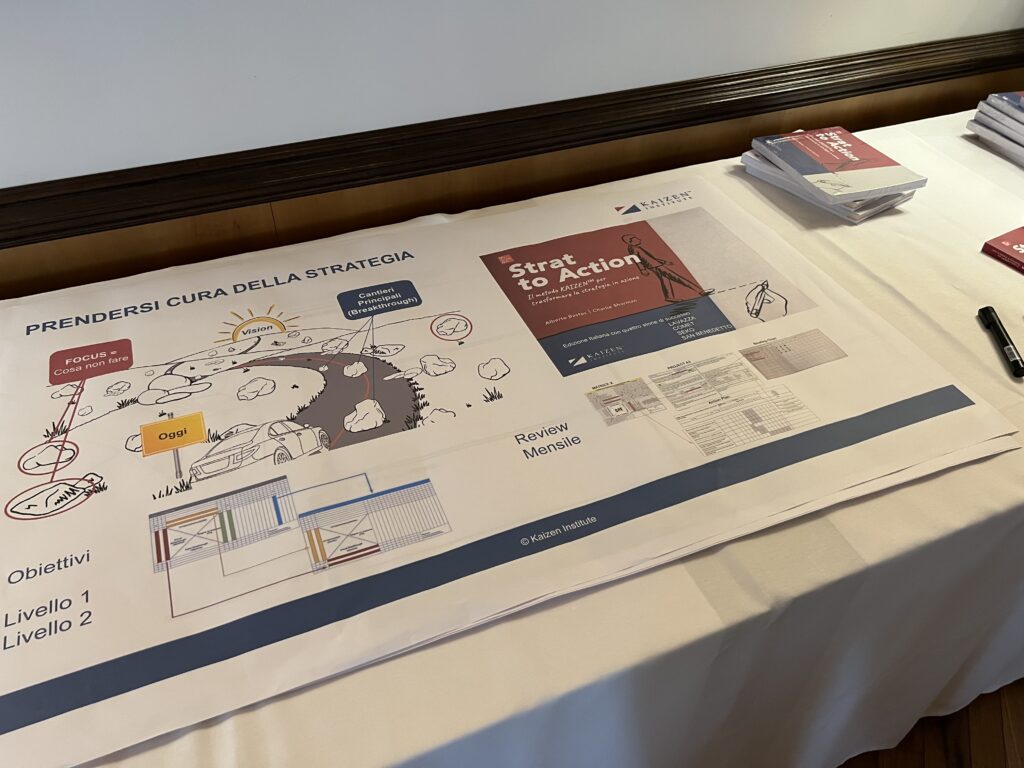

Training

The ten-year experience continues to be permeated by constant training courses. Safety training as the most important. Brazing techniques courses for the production of semi-finished pipes, essential for the refrigeration circuit of heat pumps. Lean manufacturing, thanks to the support of external entity such as the Kaizen Institute.

The internal Customer Satisfaction Office provides to the installer and distributor the support in various activities, on-line and on site. Guidelines, remote monitoring, on field commissioning support are part of them.

VISIT OUR WEBSITE