We are now at midpoint of the continuing “phase down” on the use of HFC refrigerants as detailed within the F Gas regulations. HFC availability has reduced to 45% of that in 2015 and many products placed on the market are now required to utilise refrigerants with GWP’s < 150. This has resulted in an increase in the use of low GWP refrigerants such as Hydrocarbons, Hydrofluoro-Olefins and CO2.

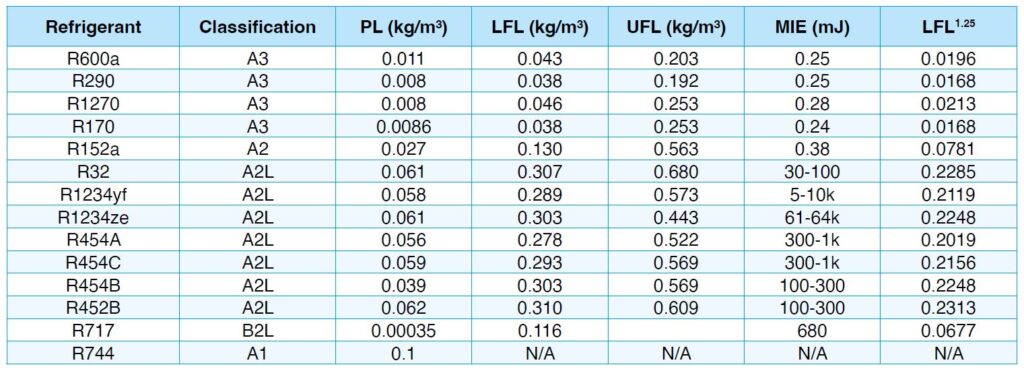

A selection of frequently used refrigerants flammability properties

PL Practical Limit

LFL Lower Flammability Limit

UFL Upper Flammability Limit

MIE Minimum Ignition Energy

These refrigerants are being used in a wide range of applications:

- Domestic heat pump

- Small split air conditioning

- Small multi-split air conditioning

- Commercial fridges and freezers

- Temporary air conditioning

- Air handling units

- Supermarket refrigeration systems

For many decades the refrigeration, air conditioning and heat pump industries have been used to dealing with non-toxic, non-flammable refrigerants. We now need to upskill to enable us to safely design, select, install, service and decommission systems designed to work on low GWP refrigerants and the hazards that they bring.

Many projects across Europe have shown that if all interested parties including, the refrigerant manufactures and their distributors, consultants, architects, and facilities management companies, amongst others, work together, these refrigerants can be used without too much difficulty.

If these systems are designed correctly, the risk of either fire or explosion can be mitigated. The service technician, however, who may be the least qualified has to undertake the higher risk tasks, sometimes with very little experience and or no training. Having worked within the training and education sector of our industry for over thirty years, one thing I have learnt is that voluntary training and assessment is only undertaken by the minority.

It is therefore imperative that the ongoing review of the F Gas regulations within Europe as well as the regulation being created within the UK ensures that mandatory training of natural persons involved in the handling of flammable or high pressure refrigerants is included.

The recent document issued by Air Conditioning and Refrigeration Association (AREA) suggested three new areas of competency assessment (theory and practical):

- Flammable large systems

- Flammable small systems

- Systems using high pressure refrigerants

This seems a sensible suggestion. We have certification schemes in the UK that currently comply with most of the criteria contained within the skills matrix suggested by AREA. It would therefore be a simple task to upgrade them to meet the criteria suggested by AREA.

It is very important that practical competencies are included within the proposed AREA skills matrix. In the UK it is thought that because a technician holds a valid category 1 F Gas qualification that there is no requirement to reassess their practical competencies when it comes to handling flammable or high-pressure refrigerants. This is potentially very dangerous, especially as we in the UK have one awarding body that has no expiry date on their qualification. This means that someone could have gained their F Gas qualification in 2009, attend a short awareness course and be deemed competent to work with flammable or high pressure refrigerants. Even though there is no proof that they have continued working practically within the industry for the last 13 years!

When the technician is carrying out the installation, repair, or decommissioning of refrigeration, air conditioning and heat pump systems that utilises either flammable or high pressure refrigerants, is when the risk to health and safety increases. The technician needs to be trained in the following activities and tasks, over and above those required to meet the minimum competencies within EU 2015/2067. These include:

Low GWP Refrigerants

- Understanding requirements of EN378 with regard to Access categories

- Understanding requirements of EN378 with regard to location of refrigerating systems

- Understanding requirements of EN378 with regard to maximum allowable refrigerant charge calculations (Annex C)

- Understanding requirements of EN378 with regard to alternative for risk management of refrigerating systems in occupied spaces (Annex C)

- Understanding requirements of EN378 with regard to maximum refrigerant charge calculations

- Understanding requirements of EN378 with regard to Safety classification about refrigerants (Annex E)

- Carry out site specific risk assessments

Flammable Refrigerants

- Have an understanding of Dangerous Substances and Explosive Atmospheres regulations, ATEX Regulations and EN 60079-10-1:2021

- Ensuring a safe working environment

- Ensuring adequate ventilation

- Correct selection of tools and equipment to be used with a flammable refrigerant

- Preparing a system to safely undertake “hot works” on a system previously charged with a flammable refrigerant

High Pressure Refrigerants

- How CO2 systems differ from standard refrigerating systems

- Jointing of K65 Refrigeration Pipework

- Correct selection of tools and equipment to be used with a high pressure refrigerant

- Pressure testing of high pressure systems

- Evacuation and Dehydration

- Charging of CO2 in both liquid and vapour state

- Safe venting of R744

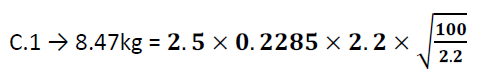

The following is an example of a calculation that a technician would need to complete to show an understanding of some of the theoretical bullet points listed above. It shows the simple formula used to determine the maximum charge allowed in accordance with EN 378 (This example is based upon the installation of a small air conditioning system to be fitted in a hotel bedroom designed to use R32.

Example

- Step 1: Access: a. Location class: II. Room volume: 100m³. Height of room 2.2m.

- Step 2: A2L (R32) LFL = 0.307kg/m³.

- Step 3: Human comfort, ceiling mounted indoor unit:

- Using equation

- and not more than the greater of m2a × 1.5 (26 × 0.307 × 1.5 =11.973) or C.3. See below.

Note: If the occupied space is greater than 250m², then use Table C.3. (This has a minimum height for a room of 2.2m. Thus, for R32, if any of the space is below ground level, then room area (250m²) x height (2.2m) = 550m³ x RCL (0.061kg/m³) =33.55kg. Or, if all of the space is above ground level, then room volume (550m³) x QLMV(0.063kg/m³) = 34.65kg and not more than m3b x 1.5= 59.865kg.

- This amount can be exceeded if the appropriate measures are taken in accordance with BS EN 378-1 C.3.2.2 or C.3.2.3

Practical Competencies

A well-publicised fire that occurred in London has resulted in a complete review of the minimum skill required for persons involved within the construction industry. There is an even greater emphasis on “competency”. To be competent you need to have the skills knowledge and wherewithal to carry out the task. Qualifications go some way to prove competency. It is therefore important to ensure the qualifications available to technicians are suitable and sufficient. As mentioned previously transference of refrigerant, into or out of the systems has the greatest potential for harm to the technician.

To safely recover a flammable refrigerant from a system, it is important to ensure that you have a safe working environment. This is achieved by ensuring that:

- Work is conducted in a well-ventilated area (either natural or forced)

- Adequate safe workspace (dry, no tripping hazards and tidy)

- Adequate lighting

- No source of ignition within the flammable zone (minimum 3m)

- Flammable gas leak detector, position dependant on characteristics of refrigerant (density greater than or less than the air in the space where the refrigerant leaks)

- Recovery machine that is safely compatible with the refrigerant safety class

- Gauge set or manifold fitted with isolating hoses

- Recovery cylinder(s) with adequate space for the total refrigerant charge within the system

- Recently calibrated refrigerant cylinder weighing platform

BS EN 378‑4:2016 states that the system pressure should be reduced to 0.3bara (absolute). This enables any remaining liquid refrigerant to evaporate and then be drawn out.

If you believe the system has a leak it is essential that the recovery process is not reduced below atmospheric pressure, to ensure a flammable mixture does not occur within the system as air containing oxygen is drawn in.

Note: Flammable refrigerant recovery and charging cylinders have left-handed threads, therefore bottle adapters must be fitted. Left-handed thread connections have a chamfered grove to identify them.

Hot Works

Whenever hot works are to be undertaken, a suitable and sufficient ATEX or DSEAR risk assessment shall be undertaken, and temporary zoning applied. When carrying out hot works on a system that has been previously charged with a flammable refrigerant, the following process should be completed prior to commencing work:

- Purge with OFN

- Evacuate system (0.3bara – Absolute)

- Agitate oil where there are large deposits, if possible, or energise the compressor crankcase heater for at least 4 hours.

- OFN purge. Use a flammable gas leak detector close to the point of purge gas escape to ascertain if the procedure is to be repeated

- Repeat as necessary

Labelling

Once the technician has completed the installation or remedial works it is important to ensure that the equipment is correctly labelled to be sure that anyone working on the system in the future is fully aware of the risk associated with the refrigerant within. The label should be attached to the compressor or condenser, or both, citing suitable information. See below for an example. A flammable warning triangle should be attached to or close to the label or close to the service valves or ports.

Refrigerant R290 (Propane)

This unit must not be located in a room or area with a volume less than XXX m³

Note: Only technicians / engineers who have been trained in safe handling of refrigerants and use of Hydrocarbon (HC) Refrigerants should work on this system.

Work on this system in a well-ventilated area or outside.

Use a local leak detector to indicate if hydrocarbon is present in the surrounding air before work commences and whist you are working, place the instrument nearby at low level, as HC’s are heavier than air.

Ensure there are no sources of ignition, flames or sparking electrical components within 3m of your working area.

If replacing components, use like-for-like replacements.

Take great care when brazing to ensure all HC has firstly been removed from the system.

USE REFRIGERANT GRADE PROPANE! R290.

Example of a label for a flammable refrigerant system

Conclusion

Over the last 5 years since the launch of various types of refrigerating equipment working with low GWP refrigerants, our training centre has carried out successful training and assessment of over 1600 technicians under the F Gas scheme. Whereas, approximately 650 have completed flammable training and only 225 have completed CO2 training. I would expect this ratio to be true of most assessment centres across Europe. Therefore, left to their own devices the typical technician has not reskilled to ensure competency when handling low GWP refrigerants. The only way this will happen is if legislation demands it.

Kelvin Kelly