ABSTRACT

In the heating and cooling sectors, heat pump technology has become a cornerstone of the global energy landscape, playing a crucial role in the future energy transition and decarbonization efforts. However, stringent regulations are being introduced to reduce both the direct and indirect environmental impacts, enhancing system performance and limiting the use of some high global warming impactful refrigerants. As a result, new technological solutions are being explored to address these evolving challenges.

The main objective of this article is to provide an overview of the heat pump technology, by examining current and future market trends, ongoing environmental regulations and safety issues during the design and installation phases. Additionally, it will discuss future trends and innovations, such as the online status monitoring of machines, the integration of renewable energy sources, and potential future control scenarios optimization for delivering heating and cooling as a service.

PAPER

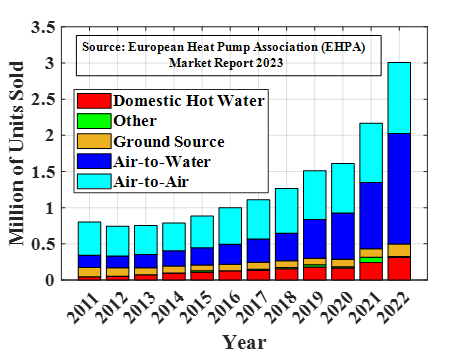

Nowadays, the increasingly stringent regulations regarding the net zero carbon emission targets set for 2050 will lead toward decreasing the energy and environmental impact of the building sector, which is currently one of the most energy-intensive worldwide. Thus, considering the energy demand for heating and cooling, which accounts for more than 50% of total energy consumption in buildings, and the global electrification resulting from the increasing use of renewable sources, this has led to a large development of heat pump systems as a potential replacement of traditional gas boilers. Specifically, according to the European Heat Pump Association (EHPA), the number of units sold has increased from about 800 thousand in 2010 to 3 million in 2022, as shown in Figure 1, with a total stock rising from 4.50 million units in 2010 to about 20 million in 2022. Most of the heat pumps currently installed in Europe are air-to-water and air-to-air types, prevalent mainly in countries such as France and Italy, and ground source, prevalent mainly in Germany and Sweden.

However, the exponential growth of heat pumps has led toward the development of new regulations regarding the reduction of indirect and direct environmental impacts of these systems. Especially for the latter, the new F-gas regulation, released in 2024, has set even stricter limits in the refrigeration and air conditioning sectors in Europe for the use of refrigerants characterized by a high environmental impact in terms of greenhouse effect and global warming. Table 1 provides an overview of the current scenario for two of the categories defined by the regulations, “Self-contained” and “Split” air-conditioning and heat pumps, according to size and temperature levels, identifying for each transitional and definitive fluid bans. Specifically, for the first category and for sizes below 12 kW, from 01/01/2027 it will no longer be possible to use fluids with Global Warming potential (GWP) greater than 150, with the possibility of using refrigerant blends such as R454C and R455A in a transitional phase. From 01/01/2032 instead, all the fluorinated refrigerants (hydrofluorocarbons/ hydrofluoroolefines) will be definitely banned, thus converging to natural fluid solutions, including Propane. Less stringent limits are instead applied for higher sizes, with the possibility after the definitive ban to use fluids with GWP up to 150 (after 01/01/2027 for sizes between 12 and 50 kW, after 01/01/2030 for sizes above 50 kW). Similar limitations were also provided for the category of Split air-conditioning and heat pumps, whereas no limitation was provided for the Automotive air-conditioning applications.

| Allowed GWP (date of the limitation) | ||

| Capacity (Q) | Self-contained air conditioning and heat pumps | Split air conditioning and heat pumps |

| (GWP<150 after 01/01/2030) R161, R454C, R455A | (GWP<150 after 01/01/2030) R161, R454C, R455A | |

| 12<Q≤50 kW | (GWP<150 after 01/01/2027) R161, R454C, R455A | |

| (GWP<150 after 01/01/2027) R454C, R455A, R161 (No HFC/HFO after 01/01/2032) R1270, R170, R600a, R290, C5H10, R744 | (<3 kg,GWP<750 after 01/01/2025, already in old F-gas regulation) R454B, R32, R452B (GWP<150 after 01/01/2027 if A/W, 01/01/2029 if A/A) R454C, R455A, R161 (No HFC/HFO after 01/01/2035) R1270, R170, R600a, R290, C5H10, R744 | |

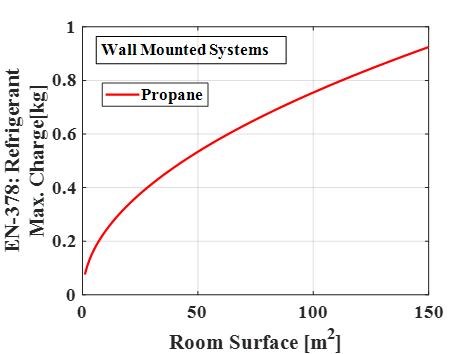

Though, the transition towards natural refrigerants in these applications raises a safety issue related to the flammability of these fluids. For example, Propane, which belongs to the ASHRAE Class A3, is strongly flammable and, therefore, a higher attention on safety concerns for these systems is needed, both during design and installation phases. The EN378 standard intervenes in this regard, which establishes the maximum limit of refrigerant charge that can be contained in an electric heat pump depending on the flammability level of the fluid used (LFL, Low Flammability Limit) and the size of the room in which, with a refrigerant leakage, potentially dangerous concentrations could be reached. For example, in the case of propane, for “Wall Mounted Systems”, the maximum allowable charge as a function of room size is shown in Figure 2. Stringent limitations will apply especially for direct expansion systems serving rooms with sizes typical of an apartment (16 to 30 m2), also leading to compliance with limitations on the size of selected components and thus penalization on the performance of the entire system. This reinforces the need for and importance of having properly trained technicians, who are able to address all the necessary safety aspects during assembly, installation, and maintenance operations of the machines. On the other hand, the regulatory agencies may revise in the future the actual fixed limitations, considering the evolution of the heat pump technologies in all the various application domains.

Thus, to best meet the challenges arising from the replacement of refrigerants, as well as to ensure high performance of the machines of the future, numerous technical innovations have been considered regarding the individual components of heat pump systems. For example, numerous arrangements have been made to reduce the volumes of heat exchangers with a view to decreasing the total refrigerant charge, with increasingly optimized construction techniques to ensure good efficiency and low manufacturing costs. To limit frost formation problems on outdoor units during winter operation, innovative surfaces for heat exchangers are being made to limit frosting phenomena. Finally, increasingly innovative compressors will be used towards a reduction of losses especially in part-load operation, ensuring increasingly low energy consumption.

Maintaining a high performance for electric heat pump systems also comes from the ability to continuously monitor the status of the individual machine, and possibly intervene with targeted maintenance interventions to restore abnormal operations. As a matter of fact, if from one side it would be possible to maintain high operational performance by means of periodical direct maintenance interventions, from the other side there are some soft faults such as refrigerant leakages and heat exchanger fouling which are quite difficult to be identified and monitored by the technicians. Therefore, in this regard, it would be useful to develop IoT (Internet of Things) devices and intelligent management of data collected via sensors, in order to forecast the maintenance intervention and avoid significant performance reduction unidentified for long periods of time. This makes it possible to optimally schedule predictive maintenance operations of refrigerant recharge or heat exchanger cleaning, as well as optimal management strategies for defrosting operations. At present, this represents a great potential especially on small machines, for which it would be possible to carry out fault identification and diagnosis with simple devices and monitoring tools at affordable prices, providing huge savings in energy consumption

Heat pump technology also lends itself to easy coupling with renewable sources of various kinds. In fact, electric heat pumps can be locally coupled with photovoltaic (to decrease electricity demand) or thermal (to increase operating temperature levels and thus performance) solar panels, especially for warmer climatic zones (e.g., Mediterranean climate). On the other hand, the use of the geothermal source is preferred in colder areas because of more stable and higher ground temperatures than those relative to the outside air.

Finally, further opportunities that can be associated with electric heat pump systems concern future scenarios of heating and cooling as a service. In these, heating and cooling will no longer be provided through the purchase of a simple machine, which then has to be operated exclusively by the end user, but as a suite of services including installation, loan for use, intelligent management and maintenance. It will be possible to implement these scenarios at different levels, whether with single machines per apartment or with large machines serving entire apartment buildings or entire districts (District Heating and Cooling, DHC). This will also enable the use of smart management strategies, demand side management, early or delayed on/off, with the goal of reducing peak energy demand and better managing the variability of energy availability from renewable sources.

Alfonso William Mauro