INTRODUCTION

In Japan, Prime Minister Suga declared carbon neutrality by 2050 in 2021, and various policies have been put forward. In the refrigeration and air conditioning industry, the biggest challenge remains the response to the “phased reduction of HFC (hydrofluorocarbon) refrigerants” agreed upon by 197 countries at the 28th Montreal Protocol Conference of the Parties held in Kigali, the capital of Rwanda, Africa, in November 2016, and specific measures are being considered for each product group in the refrigeration and air conditioning field. As of now, the reduction of HFC refrigerants in Japan is progressing smoothly and has progressed at a level corresponding to the set phased reduction amount, as will be described later. However, future responses are not necessarily optimistic, but this article describes the challenges and efforts of the refrigeration and air conditioning industry toward the “carbon neutrality by 2050” policy announced by the government.

MARKET TRENDS

Japanese Domestic Market

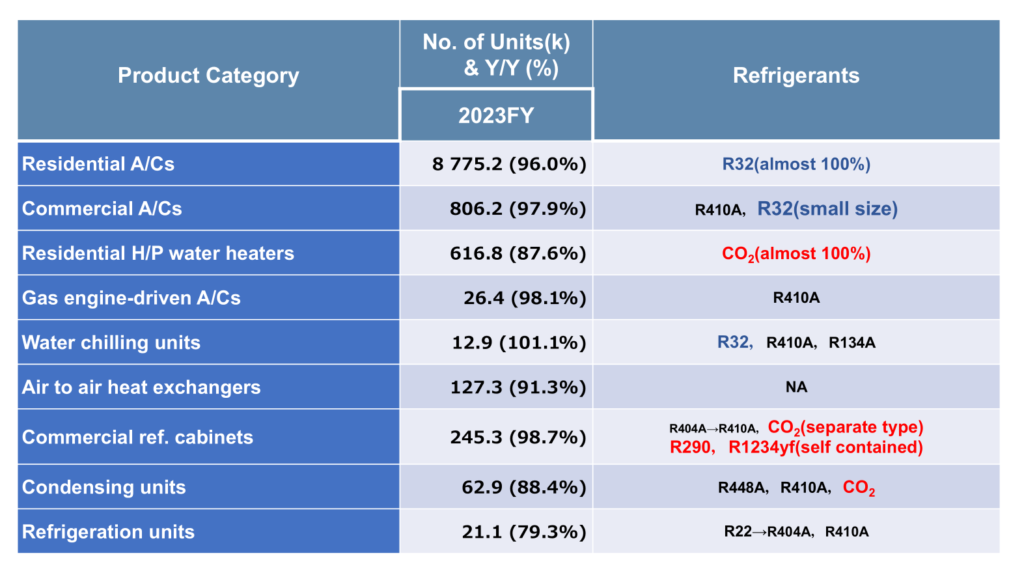

Table 1 shows the number of units shipped in Japan for each major equipment in fiscal year 2023. Because of special subsidies due to COVID19, demand for domestic air conditioners in particular temporarily increased, and some years saw record-high shipments, but since COVID19, there have been negative factors such as rising raw material costs, and the figures themselves have not necessarily exceeded those of the previous year.

ENVIRONMENTAL REGULATION TRENDS IN JAPAN

As the latest environmental policies of the Japanese government, I will focus on two major policies here. Both policies were approved by the Cabinet in October 2021 and are described in detail below.

Additionally, HFC recovery, reclamation, and destruction are lagging. To globally reduce HFC emissions, increasing recovery and systematically reclaiming and destroying HFCs are essential, with the purpose of establishing an effective refrigerant management system.

“Global Warming Countermeasures Plan”

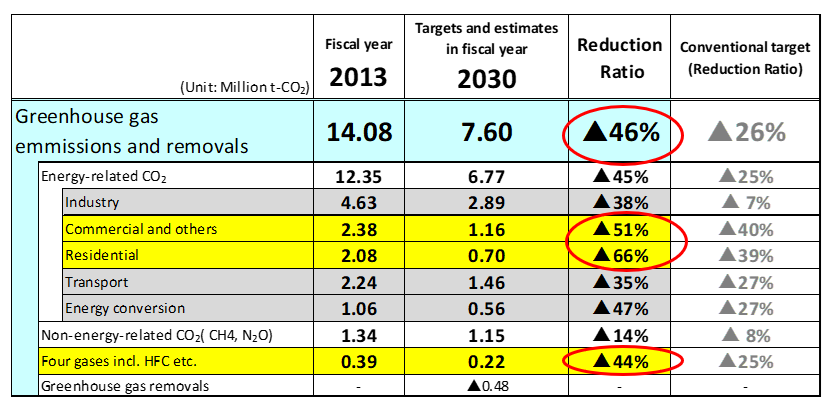

Table 2 shows the first revision in five years, and the content covers all domestic related industries, but when looking at the sector-by-sector portion of energy-related CO2 emissions, the two sectors that fall under this category are “commercial and other” and “household.” Similarly, reduction targets for the emission of “HFCs and other four gases” are presented for FY2030, with FY2013 as the base year. The key points for refrigeration and air conditioning equipment are the expansion of renewable energy and the obligation to comply with energy conservation standards for homes and buildings. Large numerical targets are imposed for the reduction rate in the commercial sector by 51%, the reduction rate in the residential sector by 66%, and the reduction rate of HFCs and other four gases by 44%.

“6th Basic Energy Plan”

This is the first review in three years since the 5th plan was issued in 2018. It is being revised to mark the 10th anniversary of the Great East Japan Earthquake. The basic policy of S+3Es (Safety, Energy Security, Economic Efficiency, Environment) has also been confirmed.

The main themes of this plan are:

- To show the path of energy policy to achieve “carbon neutrality by 2050” and the new greenhouse gas emission reduction target announced in April 2022.

- To show efforts to ensure stable supply and reduce energy costs, with safety as a major premise, while promoting climate change measures, to overcome the challenges facing Japan’s energy supply and demand structure.

The part related to the refrigeration and air conditioning field, especially in the commercial and residential fields, includes the phrase “pursuit of further energy conservation thoroughly,” and specifically, it incorporates efforts to raise the targets of the top runner program.

LAWS AND REGULATIONS IN THE REFRIGERATION AND AIR CONDITIONING FIELD

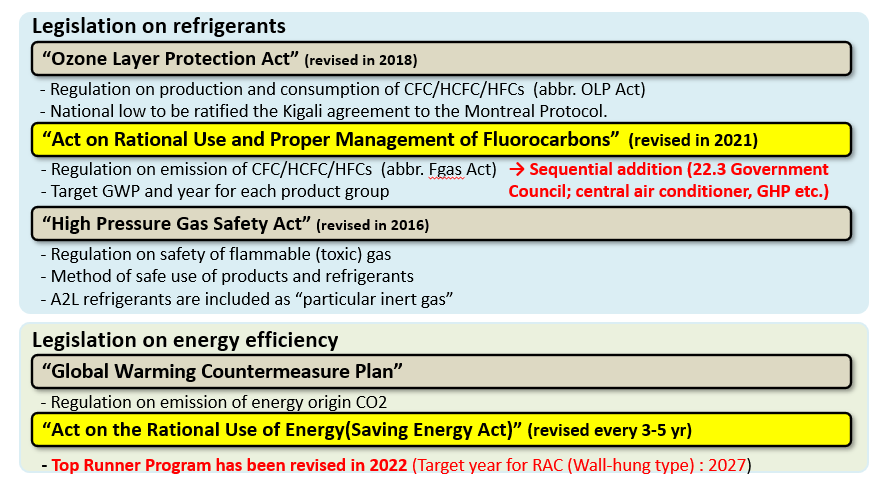

This section describes the laws and regulations in Japan that are particularly important in the refrigeration and air conditioning field.

Important laws and regulations can be broadly divided into two categories. The first is the laws and regulations regarding the refrigerants used in refrigeration and air conditioning equipment, and the second is the laws and regulations regarding the energy efficiency of the refrigeration and air conditioning equipment itself.

Figure 1. shows there are three legal regulations regarding refrigerants as follows.

Ozone Layer Protection Act (revised in 2018)

This is a domestic law regarding the production and consumption of CFC/HCFC/HFC refrigerants and ensures the Kigali Amendment of the Montreal Protocol.

Fluorocarbons Emissions Control Act (revised in 2021)

This is a law regarding the release of CFC/HCFC/HFC refrigerants and specifies the target GWP and target year for each product as a designated product. Designated products are sequentially added and set by the Fluorocarbons Working Group supervised by the Ministry of Economy, Trade and Industry of Japan.

High Pressure Gas Safety Act (revised in 2016)

This is a law regarding the safety of flammable and toxic gases and specifies the safe use of products and refrigerants.

On the other hand, there are two legal regulations regarding energy efficiency.

Global Warming Countermeasures Plan

Although not strictly a legal regulation, it is a policy aimed at reducing greenhouse gas emissions as a global warming countermeasure approved by the Cabinet in 2021, and in terms of content, the ratio of reduction in energy-related CO2 emissions is the highest.

6th Basic Energy Plan

In the Basic Energy Plan, it is positioned as an overall plan of legal regulations regarding energy conservation in specific fields. In the refrigeration and air conditioning equipment field, the Energy Conservation Act, which is reviewed every three to five years, has a strong influence. Among them, in the so-called “Top Runner Program”, top runner target values and target years are set for each equipment, and manufacturers in the industry are promoting the development of new energy-saving technologies and products toward these target values.

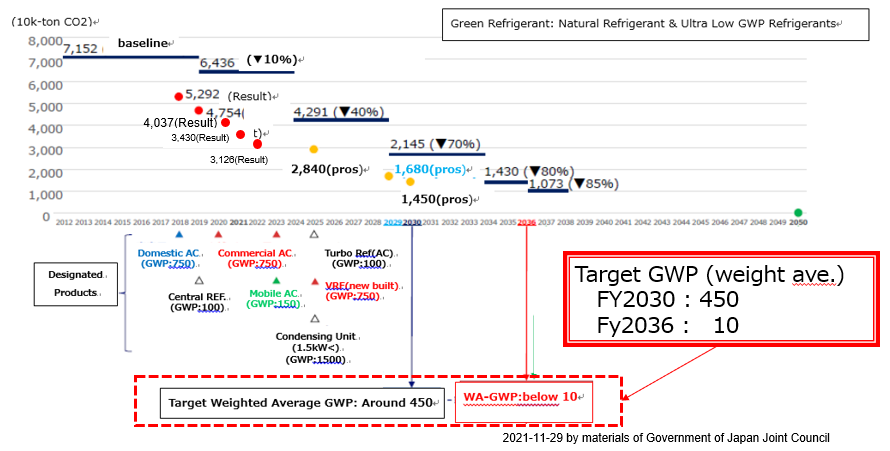

As mentioned above, Fluorocarbon Working Group, quantitative mid- to long-term reduction targets have been set as “Green refrigerant and equipment introduction scenarios” for the future, as shown in Figure 2. This shows the reduction scenario that Japan will adopt in the future in response to the global reduction steps of HFC refrigerants decided in the Kigali Amendment. The red circles in the figure show the actual HFC production and consumption, which currently show results below the target values of the Kigali Amendment. On the other hand, looking at the future, as shown in the figure, very ambitious numerical targets are shown, such as aiming for the overall HFC weighted average GWP value to be around 450 in FY2030, and for this figure to be “around 10 or less” in FY2036.

INDUSTRY EFFORTS ON ENVIRONMENTAL ISSUES

Basic Concept

To respond to the environmental regulations described above, JRAIA has listed the following two points as its basic stance in Figure 3.

- We aim to expand the use of heat pump technology and products that are highly efficient from the perspective of utilizing renewable energy.

- We aim to reduce HFC refrigerants as much as possible and adopt “green” refrigerants to lower GWP by utilizing the designated product system.

In addition, as a specific direction for responding to carbon neutrality in the refrigeration and air conditioning field, we consider the basic concept of refrigerant conversion to be the “S + 3Es” (details below), which has been set as a basic policy until now.

- Safety: Use refrigerants with low toxicity and low flammability.

- Environmental Performance: Use refrigerants with low global warming potential that do not destroy the ozone layer.

- Energy Efficiency: Use refrigerants with high energy efficiency.

- Economic Feasibility: Use refrigerants with reasonable costs and low running costs.

Needless to say, to address the various environmental issues discussed so far, it is necessary to change the refrigerants currently in use to ones with lower GWP. Although the candidate refrigerants differ depending on the characteristics of each device, it is now recognized that in the current situation, most of the alternative refrigerant candidates are not non-flammable refrigerants, but rather flammable refrigerants to some extent. While safety is the top priority, it is important to balance the three Es and select a refrigerant, and we believe it is important to select refrigerants for use in various devices.

In addition, a major perspective for curbing global warming is to curb indirect CO2 emissions. In short, this means reducing power consumption through energy conservation at the same time.

Table 3 lists the specific issues in refrigerant conversion. From the perspective of S+3Es, it is not enough to simply lower the GWP value. While safety is the top priority, if energy conservation is not properly considered, it will not ultimately lead to the curbing of global warming, so special care is required.

Response examples for multi-air conditioners for buildings

Specific responses are explained here using multi-air conditioners for buildings as an example. Multi-air conditioners for buildings(VRF) have already been designated products, but because they contain a large amount of refrigerant, risk assessments have been conducted since 2011 by air conditioner manufacturers (JRAIA) as well as national research institutes and universities, and the risks of using mildly flammable refrigerants have been evaluated in cooperation with industry, government, and academia to verify safety under various conditions. As a result of these activities, the guidelines (JRA GL-20) as an industry standard for multi-air conditioners for buildings have been made into an example standard in the Refrigeration Safety Regulations, and legal preparations for promoting the use of low-GWP mildly flammable refrigerants for multi-air conditioners for buildings have been completed. However, there are many issues regarding safety devices to comply with this industry standard, and related manufacturers are currently working on this issue. In addition, for multi-air conditioners for buildings, related construction companies (stakeholders) such as those involved in facility design and construction are often involved in safety measures, so under the initiative of the Ministry of Economy, Trade and Industry, a “stakeholder meeting” was convened to consider countermeasures to specific issues.

As a result, from the end of January 2024, three of our member companies announced new products for multi-air conditioners for buildings that use mildly flammable refrigerants.

Main features of the new products:

- Daikin Industries “VRV7” series

- Reduction of the amount of refrigerant enclosed by adopting a microchannel heat exchanger

- Adoption of a screw joint “Flareless joint”

- Adoption of a “multi-refrigerant control unit” that also functions as a shutoff device

- Hitachi Johnson Controls Air Conditioning “Flex Multi” series

- Equipped with an interlock function in the indoor unit

- Adoption of a detection alarm device

- Mitsubishi Electric “Grand Multi” series

- New lineup of refrigerant leakage prevention parts

- Adoption of an aluminum flat tube heat exchanger to reduce the amount of refrigerant

In the near future, it is expected that new products will continue to be released by companies in the industry and spread to the market.

SUMMARY

As mentioned above, the major challenges facing the refrigeration and air conditioning industry today are refrigerant conversion to curb global warming and improving energy efficiency (energy saving). In particular, the response to the “Kigali Amendment” mentioned in this paper is recognized as a major challenge that affects all sectors of the industry. For some equipment, the optimal refrigerant for specific conversion has not yet been identified, and it is no exaggeration to say that the fate of the industry will depend on the future activities of not only equipment manufacturers but also refrigerant manufacturers. In addition, refrigerant conversion for equipment requires the understanding and cooperation of related stakeholders such as equipment users, building facility design, construction, and service support, and it is likely that new efforts in various forms will be required in the future. For this reason, it is expected that mid- to long-term research and development and technological development related to introduction, the construction of social systems such as refrigerant management, and various other measures will become necessary and important. For the development of the industry, our industry association intends to tackle these issues sincerely and aim to promote steady activities with the goal of suppressing global warming.

Tetsuji Okada